We draw from our own experience as Wholesale sushi producer as well as Owners of multiple retail sushi takeaway stores and also as a Concessionaire in a David Jones Food Hall (an upmarket departmental store). We started our sushi business as a retailer but after some persuasion by many of our own customers, we started supplying sushi to various catering companies, schools, hospitals, universities and supermarkets resulting in more than 300 outlets total. As the cost of labour in Australia is always high and forever going up, automation is the ONLY way to reduce overall business costs.

Looking at the major usage of time in sushi production:

In producing sushi, the major activities can be broken down into these categories:

- Rice production

- Sushi production

- Cutting and packing

Rice production: cooking rice is usually done with automatic rice cookers, so, this is already a time saver. After the rice is cooked and rested sufficiently, some operators have the thinking that it is an ‘easy’ task to cool and mix vinegar by hand. Although traditionally, this is the way ‘shari’ (Sushi rice) is made, not many customers are willing to pay for the additional cost of manually cooling and mixing vinegar mix to the hot rice by hand. So, this is where the first major ‘automation’ can greatly improve consistency and reduce labour costs drastically. The use of Autec ASM730CE Shari Maker means the operator just needs to put the hot rice into the mixing bowl, pour the vinegar mix and press the start button. They can walk away and do other tasks while the machine mixes and cools the rice automatically.

Simple cost calculation: Let’s say the outlet makes 10 batches of shari a day. If done manually, cooling and mixing by hand may take about 10 mins/batch. Assuming a cost of $20/hour….time spent on this task will be:

10 batches x 10 mins = 100mins …or $20/60mins x 100mins = $33.33 per day. For a year of 360 working days, the cost will be: $33.33 x 360 = $11,880

Our selling price of the ASM730CE Shari Maker is A$8,900+gst delivered (Jan 2018)

For the Maki sushi production, assuming that the outlet makes 200 whole maki rolls per day (very conservative) and looking at the Rice Sheeting process as this is the slowest operation in producing maki, it takes about 30 seconds per rice sheet. The operator must also weigh the rice portion and ‘add and minus’ to get the right amount of rice for the rice sheet, say, add another 10 seconds, so a total of 40 seconds/rice sheet.

Simple calculation for 200 rice sheets x 40 seconds/sheet will cost 200x40sec = 8000 seconds or 133.33 mins at $20/hr = $44.44/ day or for a 360 days year = $16,000

Our selling price of the ASM865CE Rice Sheeter is A$14,000+gst delivered (Jan 2018)

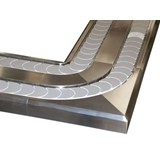

.png) Cutting of Maki sushi requires some skill and accuracy on the part of the operator. Assuming they have this and need to cut the 200 rolls per day volume, the operator will take about 25 seconds to manually cut the whole roll accurately and consistently. This is assuming they do not have wastage due to poor cutting.

Cutting of Maki sushi requires some skill and accuracy on the part of the operator. Assuming they have this and need to cut the 200 rolls per day volume, the operator will take about 25 seconds to manually cut the whole roll accurately and consistently. This is assuming they do not have wastage due to poor cutting.

Simple calculation: 200 rolls x 25seconds = 5,000 seconds per day or 83.33 min. On a yearly basis, the operator cost 83.33min/60min x $20 x 360 days = $10,000

Our ASM250CE Maki Cutter cost: $5,500+gst (Jan. 2018)

The Maki Cutting operation should only be justified when multi slices are required per roll. For sushi businesses that cut each roll into 2 and serve them as ½ rolls, we do not suggest using a Maki Cutter as it is simple enough to just manually cut by hand.

Conclusion

As can be seen above, it is easily justified to automate a sushi production and save money. Although the above example may not be representative of your actual production volume or time taken for each operation, it can be seen that there are savings over time. Besides immediate savings, a sushi machine lasts for years and the cost after the initial purchase is minimal. It does not increase annually as labour costs do. The machine does not take leave, call in sick or complain about working conditions.

For a further discussion or to trial a machine please contact Sushi Machines Pty Ltd.