While your staff are more than aware of the dangers of cross-contamination, it's not always easy to keep your chopping boards out of harm's way by using separate boards to avoid contamination, especially in the hustle and bustle of a commercial kitchen. This is where colour-coded chopping boards can come in handy, making it easier for you and your staff to quickly identify the appropriate chopping board for the job.

A visual reminder

Without having a visual reminder of what every chopping board is for, it can be difficult to determine which one is used for what, especially if all your chopping boards look the same. With colour-coded chopping boards, you eliminate this problem. You can designate a particular colour for a certain class of ingredients, such as red for raw meats, green for fruit and salad, and blue for fish.

The following six board colour-coding system is commonly used by manufacturers of chopping boards.

- Red = raw red meats

- Yellow= raw chicken

- Brown= cooked meats

- Blue = seafood

- White = dairy and bakery

- Green = fruit and vegetables

With that said, you should still check what chopping board system your kitchen uses, as the colour-coding can vary between food businesses.

One way to make sure everyone remembers what each colour is for is by positing up a legend in the area where these boards are stored. Labels are also available to help everyone keep everything straight.

Colour-coded chopping boards aren't always the sexiest chopping boards in the industry since they are made of plastic. This makes them harder on the edges of knives, but it also means they can be washed in the dishwasher. The fact that they are made of plastic usually means they are cheaper too.

Furthermore, plastic is one of the few materials used in chopping boards that can be coloured, which allows employees to quickly tell them apart. Colour-coded chopping boards can be bought as part of a set with a rack included or a rack can be purchased separately. The rack allows your staff to more easily access the right cutting board without risking transference from their hands.

Note that you can also get various utensils that are colour coded to further avoid the problem of cross contamination.

What is cross contamination?

To understand the value of colour-coded chopping boards, understanding precisely what cross contamination is and how it can be prevented is critical. Cross contamination refers to the transfer of dangerous bacteria from one ingredient to another, which can occur directly, when the different ingredients come into contact with each other, or via hands, utensils, chopping boards and so on.

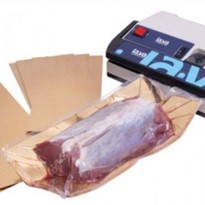

Cross contamination takes place when raw meat is handled. Poultry is usually the main culprit because it has a higher fluid content than other types of meat, which means juices tend to spread further and are more likely to come in contact with utensils, surfaces and hands. It is essential to make sure that meat, along with its juices, is kept away from other ingredients.

However, it should be noted that cross-contamination is only a problem when the ingredients in question will be eaten as is, without undergoing any form of temperature treatment. For example, if you are grilling chicken, which will then become part of a caesar salad, you shouldn't cut the chicken and then the lettuce on the same chopping board.

On the other hand, cross-contamination is less of an issue if you are making a stew, where all the ingredients will be treated thermally. However, even in such cases, it's still better to be safe rather than sorry.

It's generally a good idea to get your staff used to using the right chopping board for the right ingredient, regardless of how high or low the risk of cross-contamination is. The more they apply the principle, the more ingrained it will become, meaning there will be less chance of a grievous error that could have a massively negative impact on your business.

Is there any way to tell if an ingredient is contaminated?

Unfortunately, there's really no way to tell if an ingredient is contaminated, especially when it comes to meat. This is why all raw ingredients should be treated as if they are a potential source of contamination, which will save you a lot of heartache in the long run. The only way to really tell if something is contaminated is to get it tested in a laboratory, which simply doesn't make sense in terms of cost-efficiency and duration.

This doesn't just apply to meat, though. For example, any vegetables that are clearly dirty could be a source of contamination as could fruit and salad that hasn't been labelled as ready to eat. Dirty vegetables could be a source of E. coli 0157 contamination and need to be washed in running water and peeled before being consumed or suffering further processing. They should be stored separately from ready-to-eat foods.

Fruits, vegetables and salads that have been labelled ready-to-eat don't present the same contamination risk because they have undergone various controlled procedures and have been deemed safe for human consumption after having been tested. If any of these items will be eaten raw, it is essential to keep them away from anything in the kitchen that could contaminate them.

Preventing cross contamination

To minimise the risk of cross-contamination, there are certain measures you can implement. For example, one approach would be to have different members of your staff in charge of different activities. If this isn't feasible, consider limiting the movement of staff from the area where raw ingredients are prepared to the area where ready-to-eat ingredients are kept. You also need to have a set of personal hygiene rules that need to be enforced at all times.

You need to provide some type of physical separation, which means establishing an area specifically for the preparation of raw food. This area should have its own utensils and colour-coded chopping boards to prevent any mistakes or accidents in the future.

It's a wise idea to use different sets of equipment for raw foods and for ready-to-eat foods, and this doesn't apply solely to utensils. Most pieces of equipment should be doubled up on, as the more complex the machinery, the more danger of cross contamination.