In the ice cream world, there are two types of freezers. Static & Fully Ventilated. What is the difference?

In terms of price scale, Static displays are less expensive than by fully ventilated.

A Static Freezer is much the same as what you have at home for a domestic freezer. They do not require too much maintenance. They use lower grade quality components and, the big one, you can not see the items inside the freezer. You have to open the door.

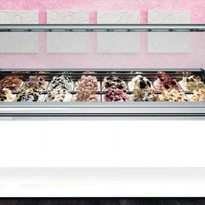

At the other end of the scale are the fully ventilated cabinets. The biggest and most noticeable difference is that you can see the product sitting high and proud in the glass. You get to eat with your eyes, so to speak.

The difference is the glass.

With a Static freezer like that in a service station, the product sits low in the cabinet and well below the horizontal sliding doors. The reason the doors are horizontal is because cold air sinks to the bottom of the cabinet.

With a fully ventilated cabinet, like that in an ice cream shop or gelateria, the product may sit high and proud in the glass area. The difference in the refrigeration system to accomplish this is vast. Fully ventilated cabinets need to achieve a cold air envelope to protect the product from heat coming through the glass. Because this envelope gets created, often the sliding doors are not required at all. The sliding doors sit outside the air envelope.

Further, because the humidity in the air is attracted to the cold like a magnet to metal, a fully ventilated system requires a glass heating system so that you can see the product and not the rainfall of water on the glass.

The key differences between Static and Ventilated systems can be summarised as:

|

Ventilated |

Static |

|

The display of the gelato is raised above the evaporator – better viewing of the display |

Display of the gelato must be below the load line and the load limit is always below at least a good portion of the evaporator. Poor visibility of displayed product |

|

You can mound the gelato over the tray for high customer appeal |

It is almost impossible to mound gelato over the tray unless the tray is lowered so the top of the display is below the load limit |

|

Ventilated displays are available in all sizes from 4 tray up to 24 tray - using 5L trays |

Most static displays can only hold a single row of 5 litre trays |

|

Most double row displays have high speed high efficiency defrosting around 3 to 6 minutes duration |

Static freezers either have no defrost at all or have a slow defrost cycle lasting many minutes in duration that effects the quality of the product |

|

For optimal performance, ventilated displays should have an overnight manual defrost 1 to 2 times per week |

Static displays due to their design can remain without overnight manual defrosts for up to 4 weeks. |

|

Refrigeration systems usually have a higher build cost |

Refrigeration systems usually are a simple design and lower build costs |

I hope this has answered your question.