How do vacuum packing units improve the durability of cooked or raw food?

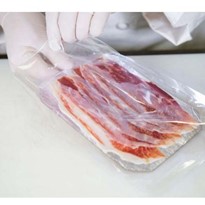

Michael Sabbatucci Jnr (Sammic Australia): Removing the air that surrounds food inhibits growth of bacteria, mould and yeast, because these and other spoilage micro-organisms need oxygen to grow. Once most air is removed and the pouch is sealed, oxygen levels continue to drop while carbon dioxide levels increase. The low oxygen, high carbon dioxide environment significantly reduces the growth of normal spoilage organisms, allowing longer shelf life.

How has vacuum packing technology developed over the years?

Originally this technology was used to prolong the life of the products; today it is also used for low-temperature cooking (Sous Vide), marinades and new cooking techniques such as cold osmosis and transparency by vacuum which involves transfusion of food cells with different flavours.

What are the hallmarks of European vacuum packing technology?

Definitely its overall quality – not only the manufacturing of every single part, but also the attention to detail in producing the complete machine from start to finish. At Sammic Australia, we share a philosophy with our European suppliers, 'Buy Once, Buy Quality'.

What are the major differences between top quality vacuum packing machines and the lower end of the range?

First is the pump quality which in terms of vacuum packing is the heart and soul of the machine, therefore it has to be of the highest quality, which is why we at Sammic only use the German pump produced by Busch. Not only are these pumps known to be the best pumps in the world, but they also have service branches all over Australia.

Top units have a clean stamped/pressed chamber and wireless sealing beams to avoid food traps and hazards.

All quality parts are used throughout the machines, allowing the manufacturer to give high end warranties.

And then there's the service. A big difference between top quality vacuum packaging machines and the lower end of the range is not only to do with the machine itself. A true top quality machine comes from a manufacturer with distributors who have to be very knowledgeable on the product itself and who have the service to back the product 100 per cent. For example, on-site training if required and spare parts in stock to support the end users if they require a part as soon as possible.

How important is it to use the right type of vacuum packing machine for the specific job?

It is imperative that the right vacuum packaging machine is used for the specific job, which is why at Sammic Australia we like to talk to the customer and ask them what they are packaging in terms of size, wet dishes, dry dishes etc. We have a large range of machines to suit everyone's needs from a small out-of-chamber machine to a large swing lid machine for mass production kitchens and manufacturers.

Along with sizing there are also different types of machines, so it really pays to talk with the customer to get a sense of what they are going to use it for. And in some circumstances advise them on what other applications they can use it for, therefore value adding to their purchase. So from our point of view, it is very important that the right type machine is sold to the customer for their specific needs.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)